CHEMICAL COMPOSITION LIMITS FOR ALUMINUM ALLOYS

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

OTHERS |

OTHERS |

Al |

|

EACH |

TOTAL |

MIN. |

|||||||||

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

— |

0.04 |

0.03 |

0.03 |

— |

99.70 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

— |

0.05 |

0.03 |

0.03 |

— |

99.60 |

|

|

|||||||||||

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

— |

0.05 |

0.03 |

0.03 |

— |

99.50 |

|

1350 |

0.10 |

0.40 |

0.05 |

0.01 |

— |

0.01 |

0.05 |

— |

0.03 |

0.10 |

99.50 |

|

1145 |

0.55 Si + Fe |

0.05 |

0.05 |

0.05 |

— |

0.05 |

0.03 |

0.03 |

— |

99.45 |

|

|

1100 |

0.95 Si + Fe |

|

0.05 |

— |

— |

0.10 |

— |

0.05 |

0.15 |

99.00 |

|

|

2024 |

0.50 |

0.50 |

|

|

|

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3003 |

0.6 |

0.7 |

|

|

— |

— |

0.10 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3004 |

0.30 |

0.7 |

0.25 |

|

|

— |

0.25 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3005 |

0.6 |

0.7 |

0.30 |

|

|

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3104 |

0.6 |

0.8 |

|

|

|

— |

0.25 |

0.10 |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4004 |

|

0.8 |

0.25 |

0.10 |

|

— |

0.20 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4104 |

|

0.8 |

0.25 |

0.10 |

|

— |

0.20 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4043 |

|

0.8 |

0.30 |

0.05 |

0.05 |

— |

0.10 |

0.20 |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4045 |

|

0.8 |

0.30 |

0.05 |

0.05 |

— |

0.10 |

0.20 |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5005 |

0.30 |

0.7 |

0.20 |

0.20 |

|

0.10 |

0.25 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5050 |

0.40 |

0.7 |

0.20 |

0.10 |

|

0.10 |

0.25 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

|

|

0.10 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5252 |

0.08 |

0.10 |

0.10 |

0.10 |

|

— |

0.05 |

— |

0.03 |

0.10 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5056 |

0.30 |

0.40 |

0.10 |

|

|

|

0.10 |

— |

0.05 |

0.15 |

Rem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5657 |

0.08 |

0.10 |

0.10 |

0.03 |

|

— |

0.05 |

— |

0.02 |

0.05 |

Rem. |

|

5182 |

0.20 |

0.35 |

0.15 |

|

|

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Rem. |

|

6061 |

|

0.7 |

|

0.15 |

|

|

0.25 |

0.15 |

0.05 |

0.15 |

Rem. |

|

7075 |

0.40 |

0.50 |

|

0.30 |

|

|

|

0.20 |

0.05 |

0.15 |

Rem. |

CHEMICAL COMPOSITION FOR COPPER ALLOYS

| Material designation |

COMPOSITION %

|

|||||||||

|

Element

|

Cu

|

Ag

|

Bi

|

O

|

P

|

Pb

|

Other elements (see note)

|

|||

| Symbol |

Number

|

Total

|

Excluding

|

|||||||

| Cu-ETP |

CW004A

|

min.

max. |

99,90(1)

- |

-

- |

-

0,0005 |

-

0,040(2) |

-

- |

-

0,005 |

-

0,03 |

Ag. O

|

| Cu-FRHC |

CW005A

|

min.

max. |

99,90(1)

- |

-

- |

-

- |

-

0,040(2) |

-

- |

-

- |

-

0,04 |

Ag. O

|

| Cu-OF |

CW008A

|

min.

max. |

99,95(1)

- |

-

- |

-

0,0005 |

-

-(3) |

-

- |

-

0,005 |

-

0,03 |

Ag.

|

| CuAg 0,04 |

CW0011A

|

min.

max. |

Balance

- |

0,03

0,05 |

-

0,0005 |

-

0,040 |

-

- |

-

- |

-

0,03 |

Ag. O

|

| CuAg 0,07 |

CW0012A

|

min.

max. |

Balance

- |

0,06

0,08 |

-

0,0005 |

-

0,040 |

-

- |

-

- |

-

0,03 |

Ag. O

|

| CuAg 0,10 |

CW0013A

|

min.

max. |

Balance

- |

0,08

0,12 |

-

0,0005 |

-

0,040 |

-

- |

-

- |

-

0,03 |

Ag. O

|

| CuAg 0,04P |

CW0014A

|

min.

max. |

Balance

- |

0,03

0,05 |

-

0,0005 |

-

-(3) |

0,001

0,007 |

-

- |

-

0,03 |

Ag. P

|

| CuAg 0,07P |

CW0015A

|

min.

max. |

Balance

- |

0,06

0,08 |

-

0,0005 |

-

-(3) |

0,001

0,007 |

-

- |

-

0,03 |

Ag. P

|

| CuAg 0,10P |

CW0016A

|

min.

max. |

Balance

- |

0,08

0,12 |

-

0,0005 |

-

-(3) |

0,001

0,007 |

-

- |

-

0,03 |

Ag. P

|

| CuAg 0,04(OF) |

CW0017A

|

min.

max. |

Balance

- |

0,03

0,05 |

-

0,0005 |

-

-(3) |

-

- |

-

- |

-

0,0065 |

Ag. O

|

| CuAg 0,07(OF) |

CW0018A

|

min.

max. |

Balance

- |

0,06

0,08 |

-

0,0005 |

-

-(3) |

-

- |

-

- |

-

0,0065 |

Ag. O

|

| CuAg 0,10(OF) |

CW0019A

|

min.

max. |

Balance

- |

0,08

0,12 |

-

0,0005 |

-

-(3) |

-

- |

-

- |

-

0,0065 |

Ag. O

|

| Cu-PHC |

CW0020A

|

min.

max. |

99,95(1)

- |

-

- |

-

0,0005 |

-

-(3) |

0,001

0,006 |

-

0,005 |

-

0,03 |

Ag. P

|

| Cu-HCP |

CW0021A

|

min.

max. |

99,95(1)

- |

-

- |

-

0,0005 |

-

-(3) |

0,002

0,007 |

-

0,005 |

-

0,03 |

Ag. P

|

|

NOTE: the balance of the other elements (excluding copper) is defined as the sum of Ag, As, Bi, Cd, Co, Cr, Fe, Mn, Ni, 0, P, Pb, S, Sb, Se, Si, Sn, Te and Zn, excluding the other elements for which the value is already indicated.

(1) Including silver, up to a maximum of 0.015%. (2) An oxygen content of 0.060% is permitted, with a prior agreement beteween the seller and the buyer. (3) Then oxygen content must be in accordance with the hydrogen embrittelment test. of EN 1976. |

||||||||||

CHEMICAL COMPOSITION of BRASS STEEL ALLOYS

| UNS No. | AS No. | Common Name | BSI No. | ISO No. | JIS No. | Copper % | Zinc % | Lead % | Other |

| C21000 | 210 | 95/5 Gilding metal | - | CuZn5 | C2100 | 94–96 | ~5 | - | |

| C22000 | 220 | 90/10 Gilding metal | CZ101 | CuZn10 | C2200 | 89–91 | ~10 | - | |

| C23000 | 230 | 85/15 Gilding metal | Cz103 | CuZn20 | C2300 | 84–86 | ~15 | - | |

| C24000 | 240 | 80/20 Gilding metal | Cz103 | CuZn20 | C2400 | 78.5–81.5 | ~20 | - | |

| C26130 | 259 | 70/30 Arsenical brass | Cz126 | CuZn30As | C4430 | 69–71 | ~30 | Arsenic 0.02–0.06 |

|

| C26000 | 260 | 70/30 Brass | Cz106 | CuZn30 | C2600 | 68.5–71.5 | ~30 | - | |

| C26800 | 268 | Yellow brass (65/35) | Cz107 | CuZn33 | C2680 | 64–68.5 | ~33 | - | |

| C27000 | 270 | 65/35 Wire brass | Cz107 | CuZn35 | - | 63–68.5 | ~35 | - | |

| C27200 | 272 | 63/37 Common brass | Cz108 | CuZn37 | C2720 | 62–65 | ~37 | - | |

| C35600 | 356 | Engraving brass, 2% lead |

- | CuZn39Pb2 | C3560 | 59–64.5 | ~39 | 2.0–3.0 | - |

| C37000 | 370 | Engraving brass, 1% lead |

- | CuZn39Pb1 | C3710 | 59–62 | ~39 | 0.9–1.4 | - |

| C38000 | 380 | Section brass | Cz121 | CuZn43Pb3 | - | 55–60 | ~43 | 1.5–3.0 | Aluminum 0.1-0.6 |

| C38500 | 385 | Free cutting brass | Cz121 | CuZn39Pb3 | - | 56–60 | ~39 | 2.5–4.5 | - |

|

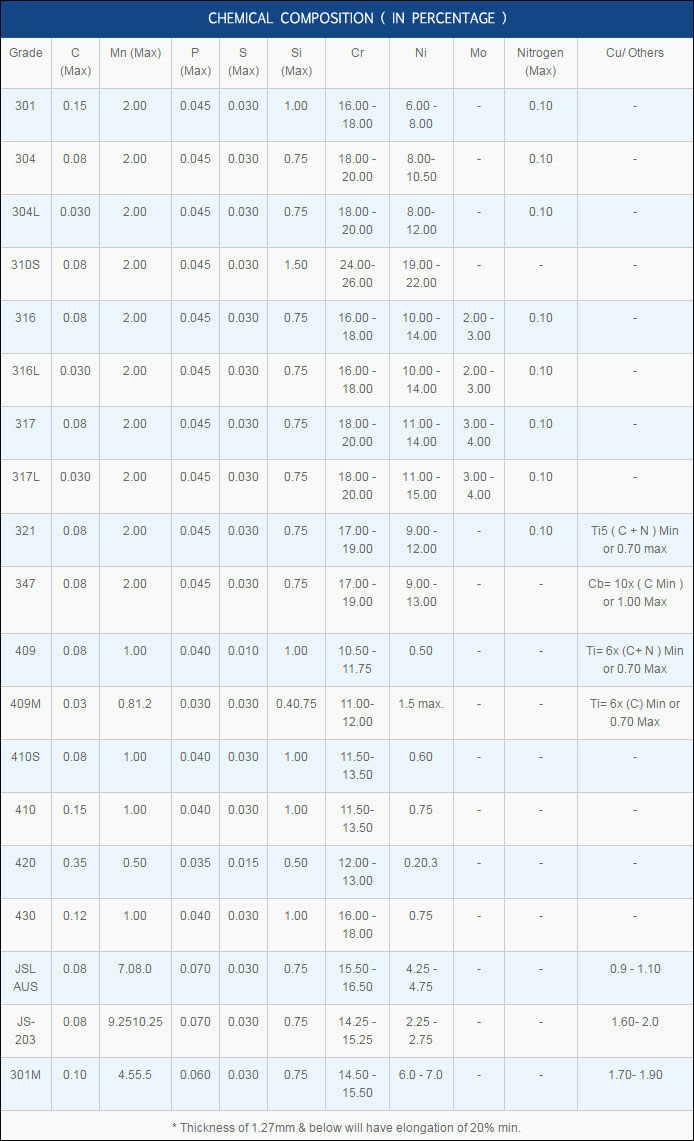

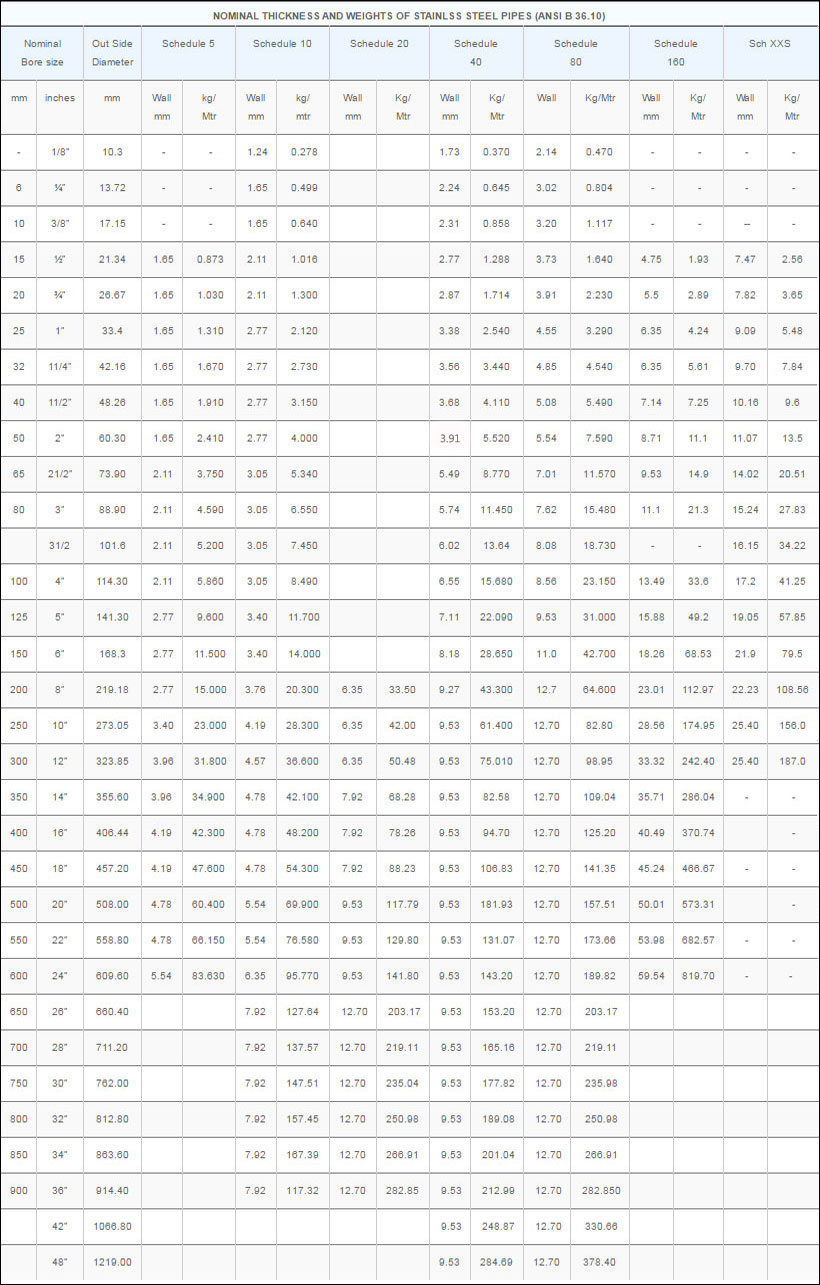

Grade

|

Tensile Strength Mpa(Min)

|

Yield Strength Mpa(Min)

|

%Age Elongation in 50mm gauge length min

|

Hardness(Max)

|

|

| BHN |

Rb

|

||||

| 301 | 515 | 205 | 40 | 217 | 95 |

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 95 |

| 310S | 515 | 205 | 40 | 217 | 95 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

| 317 | 515 | 205 | 35 | 217 | 95 |

| 317L | 515 | 205 | 40 | 217 | 95 |

| 321 | 515 | 205 | 40 | 217 | 95 |

| 347 | 515 | 205 | 40 | 201 | 92 |

| 409 | 380 | 170 | 20 | 179 | 88 |

| 409M | 430 | 275 | 20 | 187 | 90 |

| 410S | 415 | 205 | 22 | 183 | 89 |

| 410 | 450 | 205 | 20 | 217 | 89 |

| 420 | 700(max) | - | 15 | 217 | 95 |

| 430 | 450 | 205 | 22 | 183 | 89 |

| JSL AUS | 515 | 205 | 40 | 217 | 95 |

| JS-203 | 515 | 205 | 40 | 217 | 95 |

| 301M | 515 | 205 | 40 | 217 | 95 |

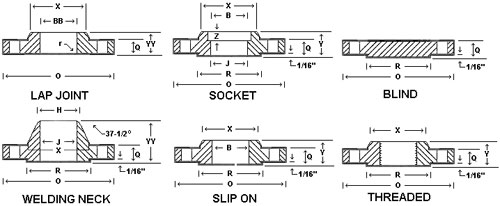

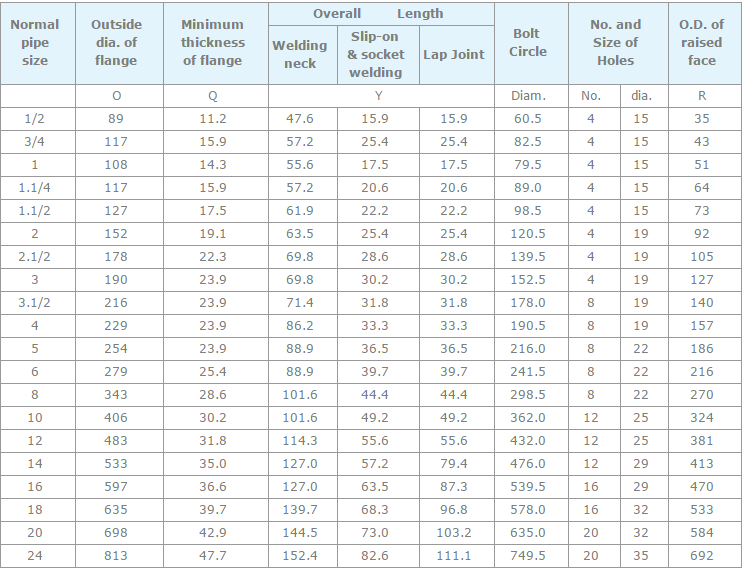

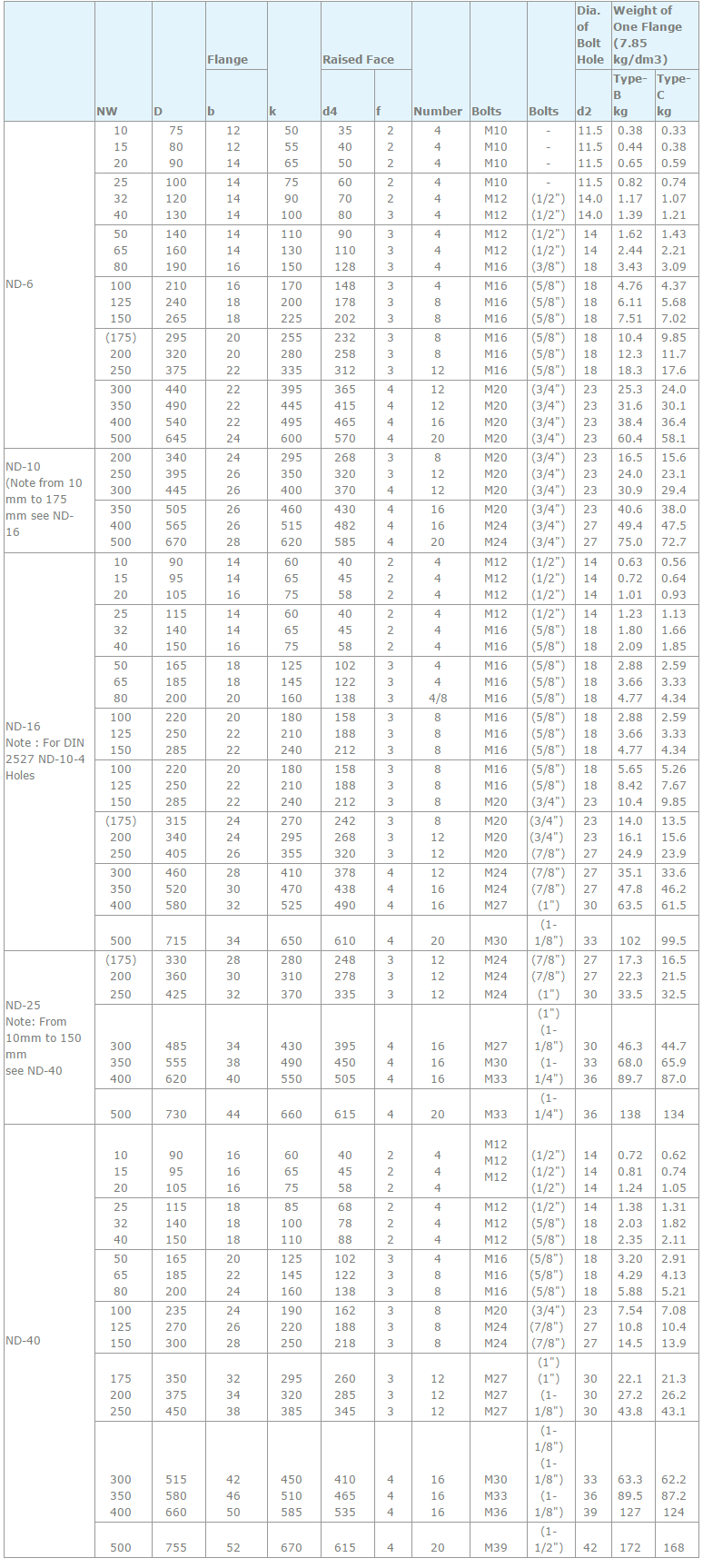

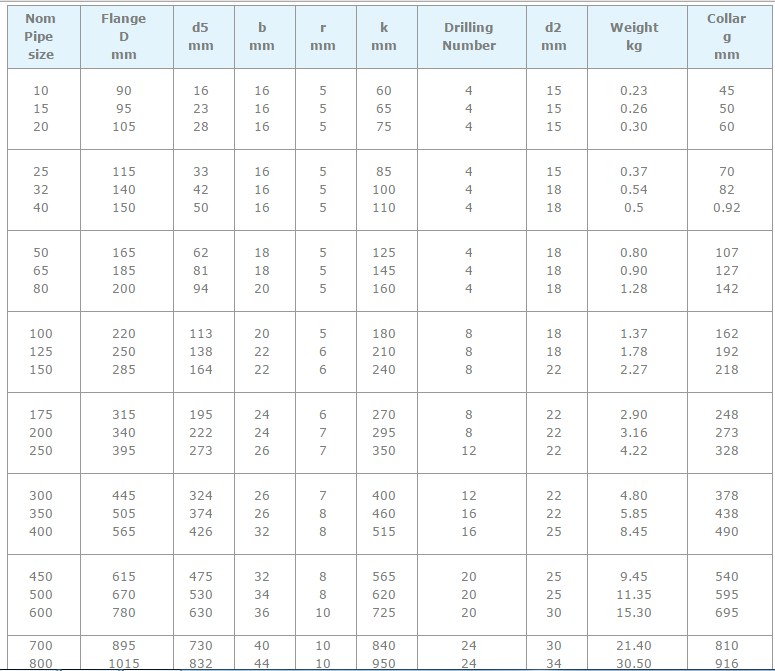

150 LB. FLANGES

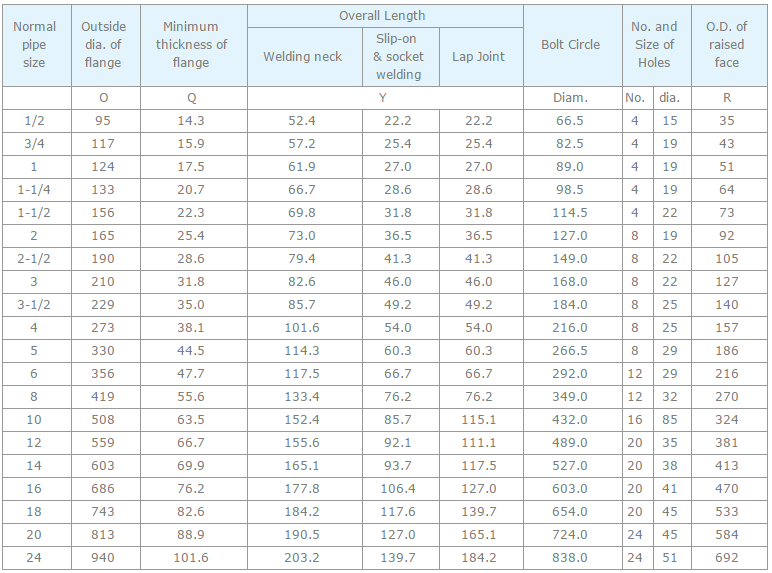

300 LB. FLANGES

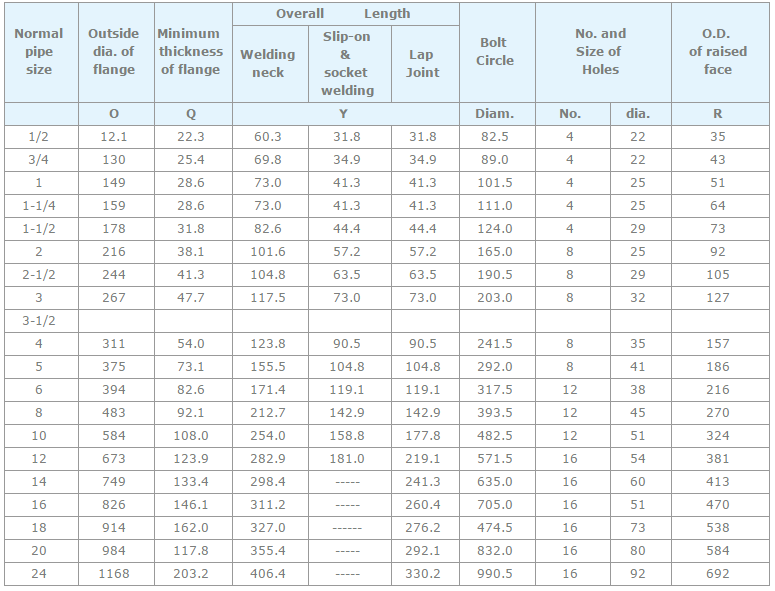

600 LB. FLANGES

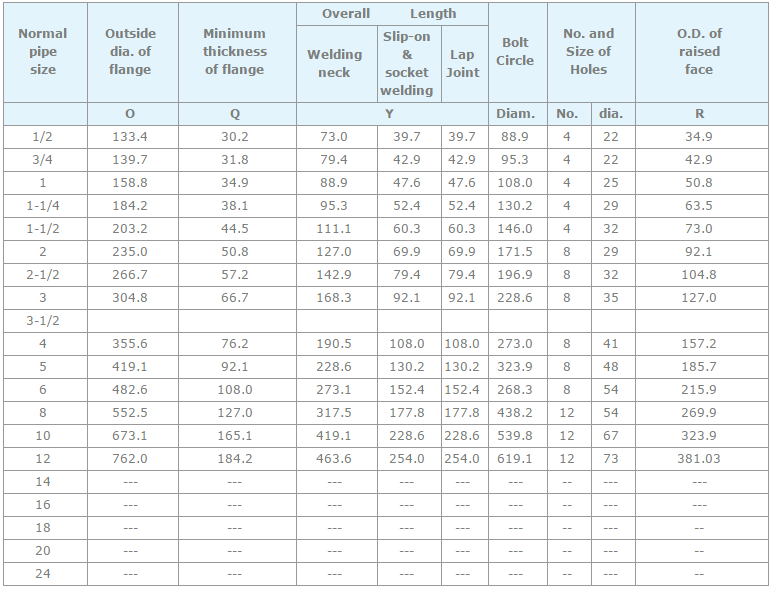

900 LB. FLANGES

1500 LB. FLANGES

2500 LB. FLANGES

WELDING NECK FLANGE BORES

DIN 2527

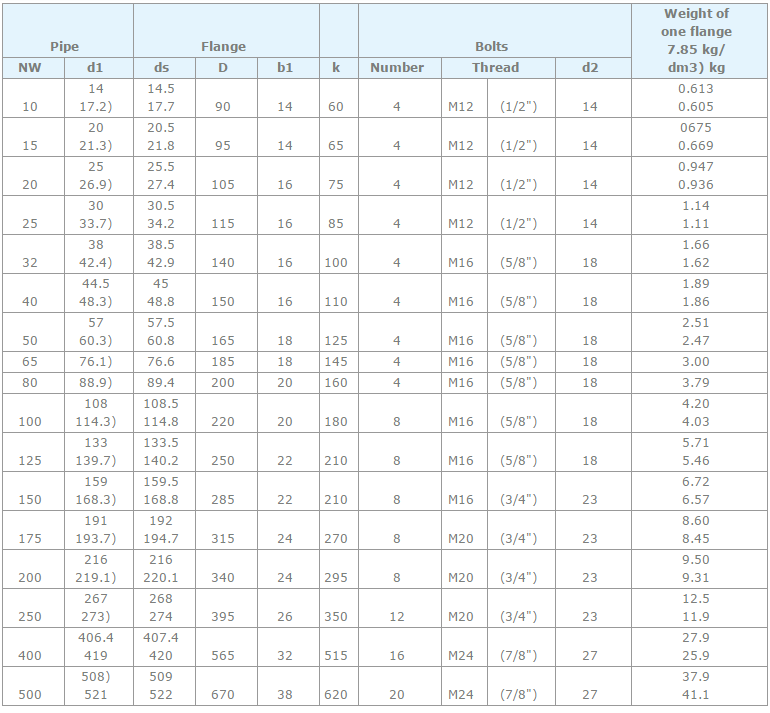

DIN 2576 FLANGES

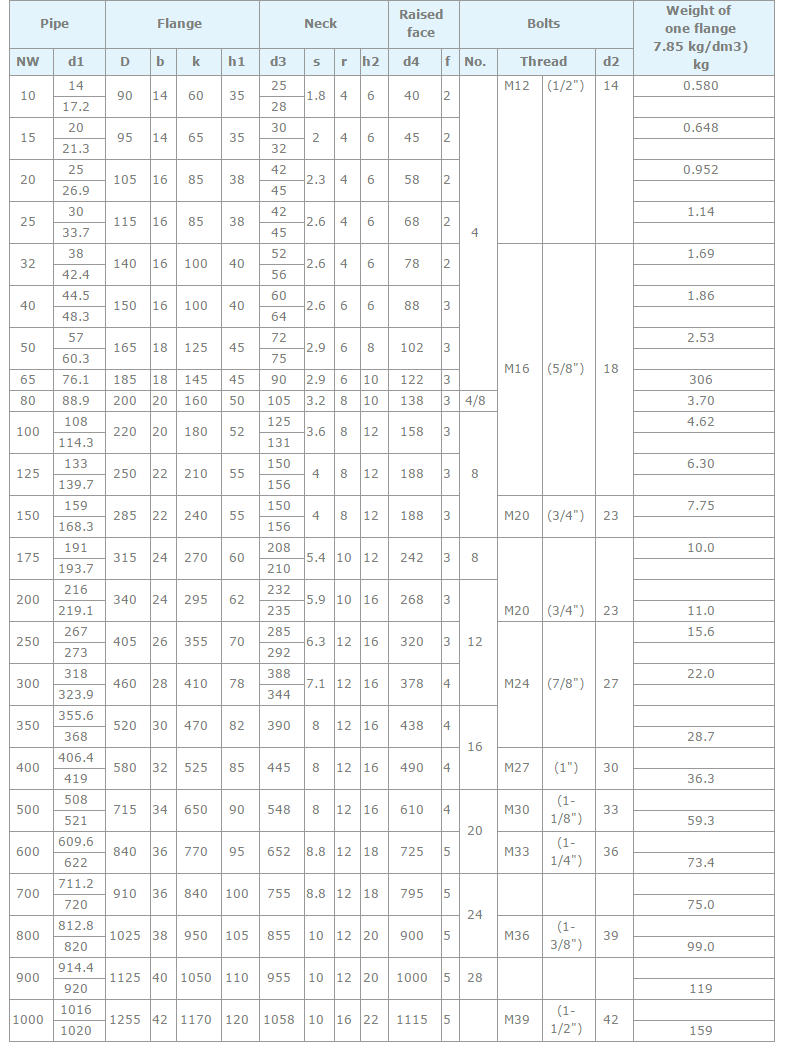

DIN 2632 WELDING NECK FLANGES FOR NOMINAL PRESSURE 10

DIN 2633 WELDING NECK FLANGES NOMINAL PRESSURE 16

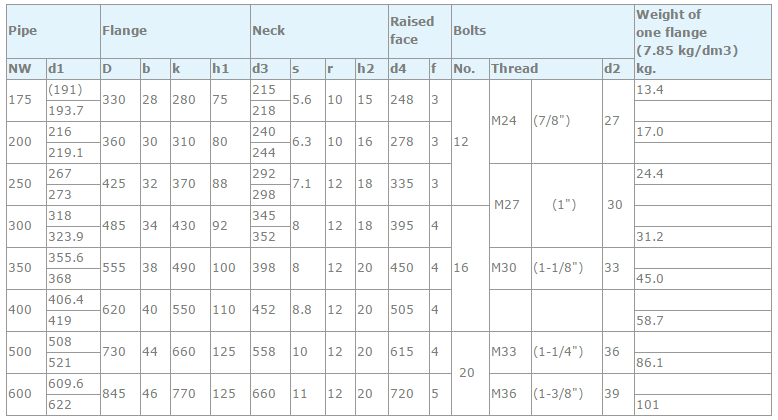

DIN 2634 WELDING NECK FLANGE NOMINAL PRESSURE 25

DIN 2642, DIN Connections LOOSE FLANGE FOR FLANGE COLLAR PN 10

DIN 2635 WELDING NECK FLANGES NOMINAL PRESSURE 40

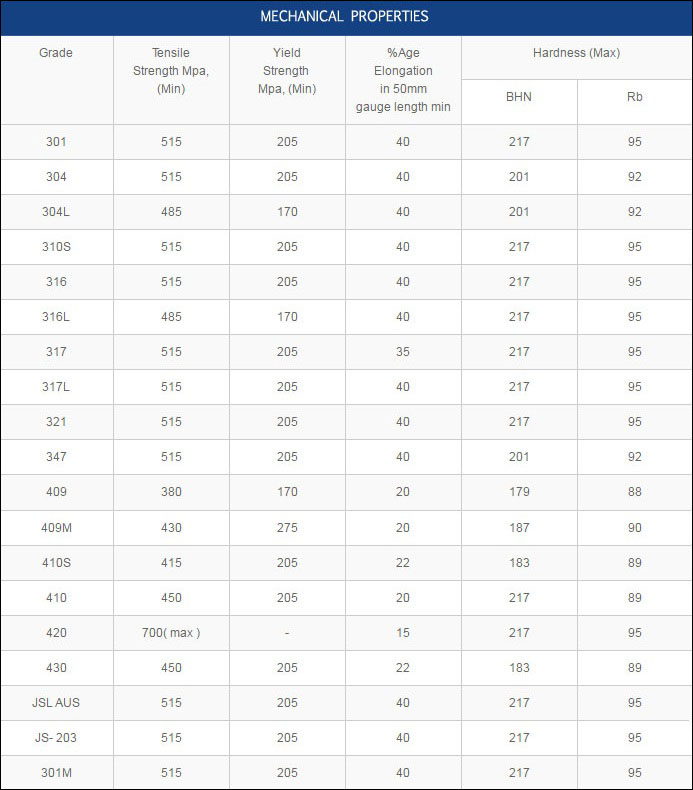

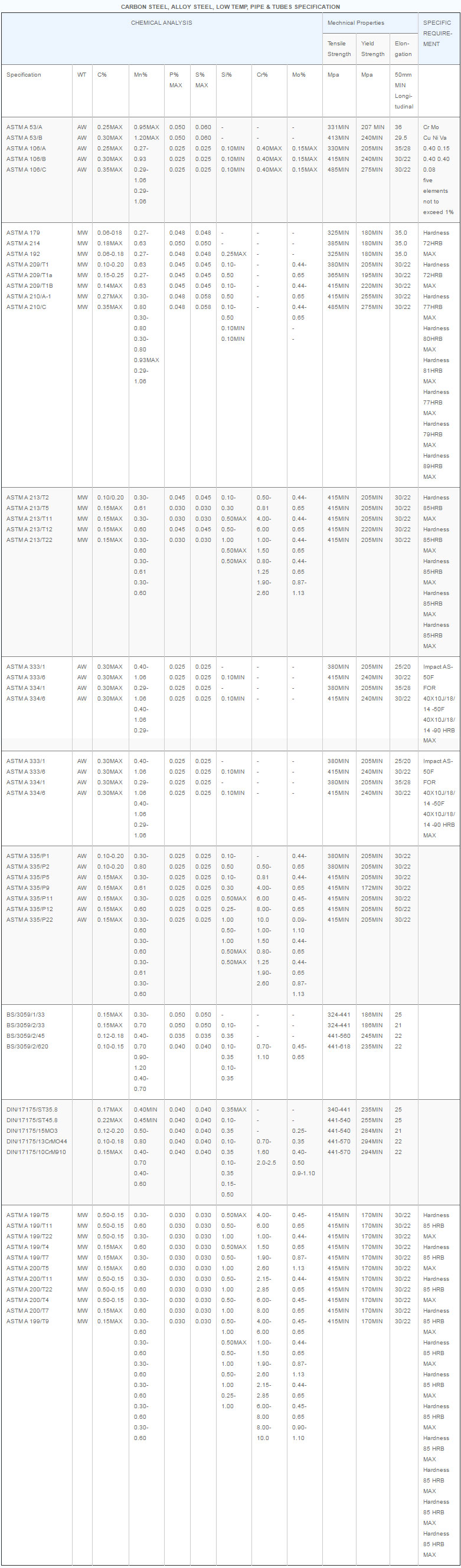

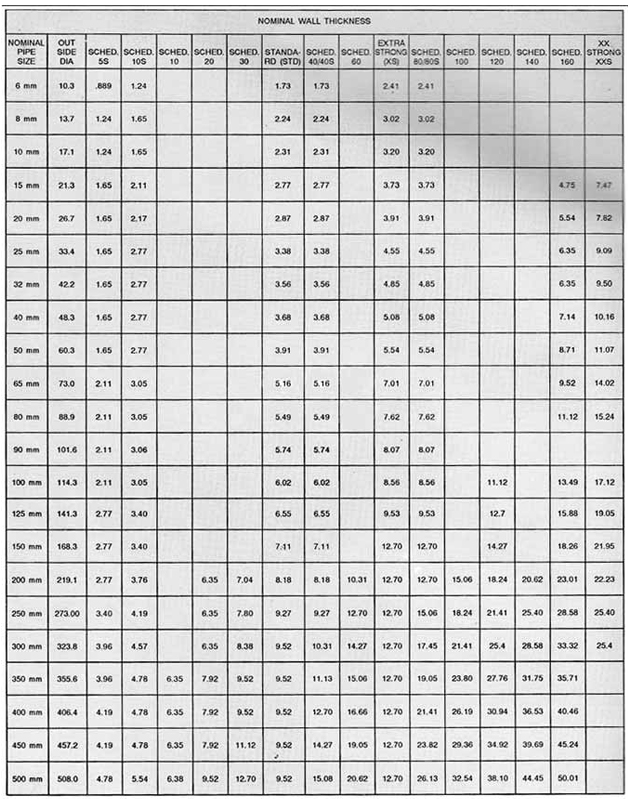

STAINLESS STEEL PIPE

| Size: | 6mm to 500mm |

| Thickness: | Sch 5, 10, 40 |

| Specification: | 202, 304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S, 409, 410, 420, 430 |

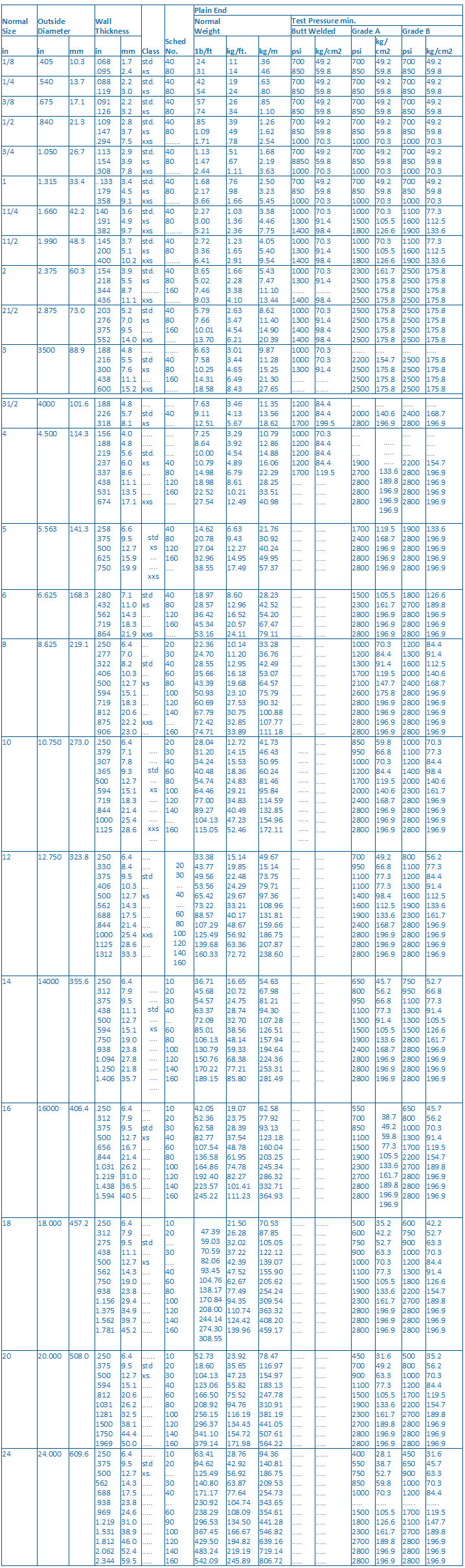

SEAMLESS PIPE

| Size | 1/4" NB TO 24" NB IN Sch 40,60,80,120,160 & XXS. (Carbon steel) |

| Carbon Steel: Specifications |

ASTM A 53, A 106, A 179, API 5L/5LX, BSS, 3059, 182, 806, 3601, 3602, DIN 17175. 2448 etc. |

Weight Formula

-

1. Weight of Stainless Steel Pipes & Tubes

OD(mm)-W.T. (mm) x W.T.(mm)x0.02466=Kg.per Mtr.

-

2. Sheet Width Required for rolled and welded pipes

O.D.(mm) - THK(mm) x 3.14=SheetWidth

-

3. Weight of Stainless Steel Sheets

Length (mtr.) x Wdth(mtr.) x Thk(mm)x8=Kg Per Sheet

-

4. Weight of Stainless Steel Circle & Blanks

OD(mm) x OD>(mm) x Thk(mm)/160/1000=Kg Per Pcs.

-

5. Weight of Stainless Steel Rounds

Dia.(mm)xdia.(mm) x 0.00623=PerMtr.

-

6. Weight of Stainless Steel Hexagonal Rods

Dia.(mm)xDia.(mm) x 0.00679=PerMtr.

-

7. Weight of Stainless Steel round Bars

Dia.(mm)xDia.(mm) x 0.00787=PerMtr.

-

8. Weight of Carbon Steel Pipes & Tubes

Dia.(mm)-W.T.(mm) XW.T.(mm) x 0.02466=Kg.PerMtr.

-

9. Weight of Carbon Steel Sheets & Plates

Length (mtr.) x Wdth(mtr.) x Thk(mm) x 7.85=Kg Per Sheet

-

10. Weight of Copper Pipes

OD(mm)-W.T. (mm) X W.T.(mm) x 0.0256=Kg.per Mtr.

-

11. Weight of Lead Pipes(appro.)

OD(mm)-W.T. (mm) XW.T.(mm) x 0.0345=per Mtr.

-

12. Weight of Lead Sheets(appro.)

Length (mtr.) XWidth(mtr.) XThk(mm) x 11.2=Kg Per Sheet

-

13. Weight of Alluminium Pipes(appro.)

OD(mm)-W.T. (mm) XW.T.(mm) x 0.0082=Kg per Mtr.

-

14. Weight of Alluminium Sheets(appro.)

Length (mtr.) X Width(mtr.) X Thk(mm) x 2.66=Kg Per Sheet

Tensile Strength Conversion Table

1. Kg/mm2 x 9.81 = N/mm2=MPa

2. PSi x 0.0007 = Kg/mm2

3. KSi x 1000 = PSi

4. Kg/mm2 x 1.422 = KSi